Our Products

-

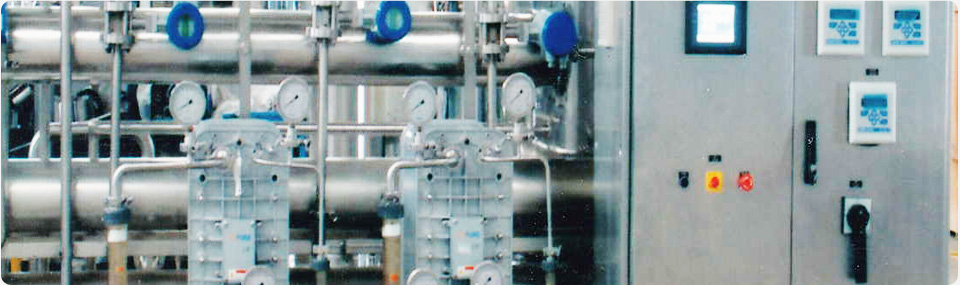

Purified Water Generation SystemThe units are custom made, modular,...

Purified Water Generation SystemThe units are custom made, modular,... -

Storage & Distribution SystemVarious items of equipments & fitments...

Storage & Distribution SystemVarious items of equipments & fitments... -

RO Water Tanks / Purified Water Tanks / WFI Tanks & Process VesselsWide experience in Design, Manufacture, Supply,...

RO Water Tanks / Purified Water Tanks / WFI Tanks & Process VesselsWide experience in Design, Manufacture, Supply,... -

CIP/SIP SystemInstall Mobile and Fixed CIP & SIP Units...

CIP/SIP SystemInstall Mobile and Fixed CIP & SIP Units... -

Sterile Pressure & Filling Vesselscomplete range of Aseptic and sterile SS containers ...

Sterile Pressure & Filling Vesselscomplete range of Aseptic and sterile SS containers ... -

Parenterals PlantsInnovative and efficient process technology for Parenterals ...

Parenterals PlantsInnovative and efficient process technology for Parenterals ... -

Injectables PlantsInnovative and efficient process technology for injectable plants applications ...

Injectables PlantsInnovative and efficient process technology for injectable plants applications ... -

Liquid Manufacturing Plant Manufacture and install quality Liquid Oral Plant (Syrups & Suspensions) ...

Liquid Manufacturing Plant Manufacture and install quality Liquid Oral Plant (Syrups & Suspensions) ... -

Ointment /Cream mfg. PlantManufacture and supply the complete customized automated Ointment / Cream manufacturing Plant ...

Ointment /Cream mfg. PlantManufacture and supply the complete customized automated Ointment / Cream manufacturing Plant ... -

Spares, Consumables & ServicesPPPL offers various Spares Consumables & Services as per required...

Spares, Consumables & ServicesPPPL offers various Spares Consumables & Services as per required...

Services

Pura-Sys Pharma Pvt. Ltd. with its in-built pool of talented and experienced expertise team for carrying out Design and detailed engineering including supply and erection of various equipments in well organize manner backed upon with various facility to make synchronous of work with decentralizing the activity to be “Just in Time” quality products & services

a) Capability

1. We understand current norms followed by various segments like Pharmaceuticals, Food, Beverage, Cosmetic, Dairy Mineral Water & Water Industry etc.

2. We understand various process techniques related to any of the above mentioned technology.

3. We are well conversant with various options available related to Process Equipments, Turn-Key or Water Generation Storage & Distribution Systems.

4. We understand and give importance to use of right components – we follow ‘QUALITY BY DESIGN’.

b) Infrastructure

1. Process know-how with in house infrastructure is the Key for timely successful completion of any project.

2. In house facility of design engineers; fabrication team; using of CAD & CAM with Pro-V facility for isometric drawings.

c) Facilities Provided to Customer

1. Manufacturing of Sanitary Skid Mounted Systems.

2. Fabrication of SS Vessels, Tanks.

3. Electro polishing – upto 10 KL tanks.

4. Ready stock of any spares & spare components required.

5. Dedicated and decentralized team for providing quality services for Orbital Welding, Boroscopy & Videoscopy and Radiography.

d) Expertise

1. Our Established credential in critical process areas.

2. Our dedicated team of professionals.

e) Detail Engg ; Services & after sales support

The Range of our Services: (Detail Engg; Service & after sales support)

- Study the Process requirements in depth and preparing the optimum solutions.

- Providing conceptual Design with a mission of concept to commissioning.

- Preparation of PFDs & P&ID for Process & Utilities requirements.

- Process Equipments; Mass & Energy Balance & Utility Consumption data with Layouts

- Electrical Load Lists with instruments required and specification.

- Equipments specification Data Sheets & Layout.

- Piping specification sheets with Layout & Isometric drawings.

- Automation & Control Architecture in details with various automation level & screen shoots.

- Qualification Documentation like DQ, IQ & DQ Protocols

- PLC & HMI Programming & SCADA Compliant features

- Equipments Fabrication as per cGMP norms

- Project Management & Installation backed with experience staff.

- Sanitary Skid; special fabricated vessels as per customer requirements; SS Vessels; tanks with or with jacket or limpet; Electro polish services required by the customer; Boroscopy or Radiography required by the customer.

- High Purity Water System /Purified Water Generation System / RO Plant / Industrial RO-Plant / DM Plant / UF / Electro ionization (EDI).

- High Purity Water Storage & Distribution System.

- Liquid Oral Plants

- Small Volume Parenterals (SVP) & Large Volume Parenterals (LVP) Plant

- Liquid Injectable Plants.

- Ointment & Cream Plants.

- Process Vessels; Blending Vessels with top mounted stirrers and bottom entry magnetic stirrers with various options.

- CIP & SIP Facilities

- Pressure Vessels & Filling Vessels.

- Mineral Water Plant complete with packaging unit i.e pouch; bottles & Jars with UV System and Ozonation supported with Lab facility set-up & ISO certifications.

Our Products

-

Purified Water Generation System

Our In-house design & engineering and manufacturingfacilities

Complete system solution available from one source. -

Storage & Distribution System

A unit which works as polishing unit for “High Purity Water Application”.

Adapted system permit compact design. -

CIP/SIP System

A well designed CIP/SIP system employing technology and a bit of process integration will facilitate you to clean one part of the plant while other areas maintain to produce product.

-

Liquid Manufacturing Plant

The Liquid Manufacturing Plants are ideal tools for the pharmaceutical industry for the production of Oral Liquids.

-

Ointment /Cream mfg. plant

Equiped with CIP & SIP facilities.

Dual Speed Anchor Agitator

Plants available with Fully/Semi Automatic systems.